Geotechnical

120-Year Old Industrial Space Renovated as Historic Destination

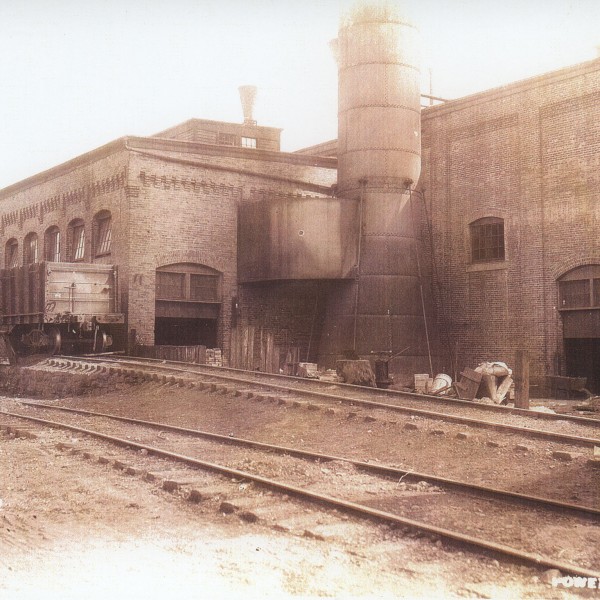

- Teaser: Lightweight aggregate from Arcosa Lightweight helps protect and stabilize a historic Birmingham structure, the Powell Avenue Steam Plant, originally built in 1895. Redeveloped by Alabama Power, the building is being preserved for its future as a downtown destination.

- Article Body Text:

Birmingham, Alabama, known as “The Magic City,” rapidly became the industrial center of the South. Today, 145 years later, it is recognized worldwide for medical research, banking, and high-tech manufacturing. The city’s historic core is undergoing revitalization, with new developments rising alongside restored landmarks from the past century.

One such landmark is the former steam plant that powered Birmingham’s downtown and streetcar system.

Clayton McKinnon, P.E., who was Director of Business Development at Hoar Construction during the restoration project, notes, “The facility was the original power plant for downtown Birmingham. We started here in 2013, decommissioning the plant, focusing on structural restoration, and getting the building stabilized for future use.”

McKinnon, now the Regional Development Director for the Gulf States Office at Agracel, oversaw the early stages of the project.

Challenge: Reducing Wall Stress

During the restoration, the team had to address the north side of the building, which had been backfilled in the 1930s when a railroad was elevated through downtown Birmingham. This created potential stresses on the walls, especially when the team needed to excavate to install waterproofing.

Geotechnical engineers from Bhate Geosciences and LBYD Civil and Structural Engineers selected lightweight aggregate from Arcosa to protect the century-old walls. McKinnon explains,

“After investigating several options, lightweight aggregate emerged as the best solution due to its properties.”

Arcosa’s lightweight aggregate, produced at the Livingston, Alabama plant, reduces the density of compacted fills by up to half. This significantly lessens lateral pressure on structures, making it ideal for sensitive projects like this one.

Results: A Stabilized Future

The 18-inch-thick brick walls of the former steam plant were successfully reinforced, with McKinnon noting, “The use of lightweight aggregate reduced stresses on the wall by about half, ensuring it will last another century.”

Although redevelopment is currently on hold, the structure has been stabilized and preserved for future use. Its next chapter as a historic destination in downtown Birmingham is ready to unfold.

- The Issue: Preserve and reduce stress on the century-old brick walls of the former steam plant during redevelopment.

- What Arcosa Did: Lightweight aggregate from Arcosa was used to alleviate stress on the walls, reducing lateral pressure on the structure.

- Why Lightweight Works: The aggregate reduces the density of compacted fills by up to half, while its high internal friction angle minimizes lateral forces.

- Result: The stresses on the brick walls were reduced by about 50%, ensuring the building’s structural stability for the next 100 years.

- Key Quote: “The use of lightweight aggregate reduced stresses on the wall by about half, ensuring it will last another century.” – Clayton McKinnon, P.E.

- Industry Context: Revitalizing historic structures often requires balancing modern engineering solutions with preservation efforts. Using lightweight materials can significantly enhance the durability of older structures without compromising their integrity.

- Lessons Learned: Choosing the right material, such as lightweight aggregate, can extend the life of historic structures while reducing future maintenance costs.

- Call to Action: Discover how Arcosa Lightweight helps in the geotechnical challenges

- Project: Powell Avenue Steam Plant Preservation

- Location: Birmingham, Alabama

- Customer: Hoar Construction

- Client: Alabama Power

Key Insights:

Quick Facts:

•

•

•

How Arcosa Helped:

•

•

Final Results

Key Quote

Context:

•

•

Explore Further

Additional Case Studies

Arcosa Lightweight Aggregate Stabilizes Soft Louisiana Soils

- Teaser: Lightweight aggregate is actively stabilizing a home in New Orleans’ historic English Turn community, tackling Louisiana’s age-old problem of land settlement. The homeowner was relieved after the landscape surrounding the property began sinking a few years ago, threatening the integrity of the driveway, walkways, and space under the house.

- Article Body Text:

Structurally, the house remained in good shape due to its construction on pilings. However, over a four-year period, the concrete paver driveway and walkways began to sink into the soft, flexible soil, as did the area under the house. Andre C. Monnot, P.E., Vice President at Principal Engineering, specified the use of lightweight aggregate sand to be pumped under the house to address the significant settlement.

To repair the driveway and sidewalks, the pavers, along with several feet of base and subbase material, were removed. Lightweight aggregate sand was then placed at a depth of approximately two feet. Friction pilings and a concrete base were also added in preparation for reinstalling the pavers.

In both the driveway and under the home, lightweight aggregate sand was selected over traditional fill due to its lighter weight and resistance to consolidation. Arcosa Lightweight’s expanded clay aggregate, produced by heating selected materials in a rotary kiln to 2,000°F, results in a durable, stable, and free-draining material that is perfect for the region’s unstable soils.

Bill Wolfe, Marketing & Technical Manager for Arcosa Lightweight, explains why the aggregate is ideal for Louisiana’s soil conditions.

“Lightweight aggregate is less than half the density of normal weight materials. By replacing about two feet of normal weight material with lightweight aggregate, we significantly reduce the vertical load. The goal in situations like this—whether for a driveway, walkway, or larger project—is to achieve net-zero weight impact on the underlying soil. Our product makes that possible.”

Contractor Pleased with Results

Raymond Burlette, currently owner of Live Oak Landscaping in Belle Chasse, Louisiana, used lightweight aggregate for the first time on this project. “We pumped the lightweight sand mixed with water under the house, and it flowed seamlessly,” Burlette explains. Due to its lower weight, the product traveled faster and more efficiently than traditional sand. For the homeowner, this lightweight aggregate offers a longer-lasting solution, and Burlette expressed eagerness to use it on future projects.

English Turn, an exclusive 2,000-acre community located eight miles from New Orleans, sits along the Mississippi River, where French forces famously outmaneuvered the English in 1699. Like many homes in the area, this house experienced sinking due to soft soils. However, thanks to lightweight aggregate, its long-term stability has been restored.

- The Issue: A homeowner in New Orleans’ historic English Turn community faced severe land settlement issues, which caused the driveway, walkways, and areas under the house to sink into the soft Louisiana soil.

- What Arcosa Did: Arcosa Lightweight provided lightweight aggregate sand to replace normal-weight fill, reducing the vertical load and stabilizing the structure.

- Why Lightweight Works: Lightweight aggregate is less than half the density of normal materials and offers free-draining properties, making it ideal for stabilizing soft soils without further consolidation.

- Result: The home’s long-term stability was restored. The lightweight aggregate not only reduced settlement but also provided a permanent solution for the sinking driveway and walkways.

- Key Quote: “The goal is to achieve net-zero weight impact on the underlying soil, and our product makes that possible.” — Bill Wolfe, Marketing & Technical Manager, Arcosa Lightweight.

- Industry Context: Lightweight aggregate proves ideal for stabilizing homes and infrastructure in areas prone to settlement, offering a long-term, cost-effective solution.

- Lessons Learned: Using lightweight aggregate to reduce vertical loads can prevent future settlement, particularly in regions with soft soils.

- Call to Action: Discover how Arcosa Lightweight can stabilize your next project with advanced lightweight aggregate solutions.

- Project: English Turn community

- Location: New Orleans, Louisiana

- Client: Private homeowner

- Project Size: Multiple areas of paver driveway and walkways

Key Insights:

Quick Facts:

•

•

•

How Arcosa Helped:

•

•

Final Results

Key Quote

Context:

•

•

Explore Further

Additional Case Studies

Arcosa Lightweight Aggregate Used to Create Vital Port Space

- Teaser: Arcosa Lightweight is frequently used in expansion projects that create vital port space along the southern tip of Louisiana. The most recent expansion project at Port Fourchon, located in Lafourche Parish, created 300 new acres for development and added an additional 10,000 linear feet of waterfront.

- Article Body Text:

This vital port serves as a land base for almost all offshore oil platforms and drilling rigs positioned in the Gulf of Mexico and acts as a foreign cargo shipping terminal. Arcosa’s lightweight aggregate material was used to build new slips that are a thousand feet wide and nearly 4,000 feet long.

Economical Land Creation

For decades, lightweight aggregate has been used as backfill to create usable land at the seaport. Some 700 acres of land have been created over the years through similar projects. “It’s really very simple,” says Bill Wolfe of Arcosa Lightweight. “Our expanded clay lightweight aggregate is more dependable and more economical for land creation, and it’s the material of choice for projects like this.”

Wolfe highlights the numerous structural and economic advantages of lightweight aggregate, noting its ability to help lower both initial construction and long-term costs.

“The lightweight being used at Port Fourchon reduces the lateral load against sheet pilings and greatly reduces the vertical loads on soils at the bottom of the sheet piling.”

“The heavier the weight of the fill, the deeper the sheet piling has to be driven to prevent toe failure. Deeper sheet piling means more steel will be needed to complete the project,” Wolfe explains. “Using our product significantly decreases the depth to which the sheet piles must be driven and reduces the chances of failure.”

Latest Project Developments

According to the latest information from the Greater Lafourche Port Commission, the Slip D development is part of the Northern Expansion project, adding 300 acres of developed property and over 10,000 linear feet of waterfront to Port Fourchon. This slip was specifically designed to accommodate larger offshore supply vessels. Although full build-out is expected to take several more years, major dredging and infrastructure work has already been completed.

Besides being a vital link to oil production, Port Fourchon also serves commercial fishermen, foreign cargo shipping enterprises, and offers a unique area for recreation and tourism.

- The Issue: Expanding vital port infrastructure to accommodate larger vessels required innovative materials to address geotechnical challenges such as high lateral and vertical loads on the sheet pilings.

- What Arcosa Did: Arcosa’s lightweight aggregate was selected to reduce lateral and vertical loads, offering significant advantages in stability and cost-efficiency.

- Why Lightweight Works: The lightweight material provided structural integrity while reducing the depth of sheet piles needed, saving costs and materials.

- Result: Slip D was designed and constructed to meet the increasing demand for larger offshore vessels. It adds over 300 acres of developed property and over 10,000 feet of new waterfront. The project is part of the ongoing Northern Expansion at Port Fourchon.

- Key Quote: “Slip D was designed to accommodate larger vessels, addressing the need for longer and wider slips compared to the older B and C facilities,” says Bill Wolfe.

- Industry Context: The use of lightweight aggregate helps reduce construction and long-term maintenance costs by limiting the depth to which sheet pilings need to be driven.

- Lessons Learned: Arcosa’s lightweight aggregate is a proven solution for large-scale maritime projects where reducing pressure on infrastructure is key.

- Call to Action: Contact our team today to learn how we can help you reduce construction costs, enhance structural integrity, and meet the demands of your project’s geotechnical challenges.

- Project: Port Fourchon Northern Expansion, Slip D

- Location: Lafourche Parish, Louisiana

- Client: Greater Lafourche Port Commission

- Project Size: 300 acres of land, 10,000 linear feet of waterfront

Key Insights:

Quick Facts:

•

•

•

How Arcosa Helped:

•

•

Final Results

Key Quote

Context:

•

•

Explore Further

Additional Case Studies

Expanded Bike Trail Benefits from Innovative Use of Lightweight Aggregate

- Teaser: Bike riders in Orland Park, IL, a suburb near Chicago, have an expanded bike trail thanks to Arcosa’s lightweight aggregate, supplied by the company’s Brooklyn, Indiana plant. Orland Park is a growing area committed to improving recreational facilities for its citizens.

- Article Body Text:

A New 1.5-Mile Bike Trail Overcomes Challenging Terrain

A new 1.5-mile bike trail, connecting two existing trails, was constructed through challenging terrain. “The site of the trail is in a swampy, marshy area bordering a large drainage ditch and a pond,” says Jack Moore, Arcosa’s geotechnical market manager. “There was also a steep slope running alongside the trail to contend with.”

“The road parallel to the bike path had been widened roughly a decade ago. Back then, developers found expanded shale lightweight aggregate (LWA) to be the perfect solution for similar challenging site conditions, and as it turns out, lightweight would once again come into play,” says Wolfe.

Two Challenges: Poor Soil and a Steep Slope

A subsurface investigation by the owner’s geotechnical engineer revealed layers of compressible soils just below the existing grade, precisely where the embankment for the newly widened path would need to go.

To address settlement concerns, the geotechnical engineer recommended using lightweight aggregate (LWA) with no more than 70 pounds per cubic foot density. Such a low-density granular fill would reduce applied pressures on the compressible soils. However, the slope still needed to be managed.

“A reinforced slope system, called Tensar Sierra® Slope, was chosen to deal with that challenge,” Moore says. “Arcosa Lightweight was placed in the reinforced fill zone of the Sierra system. Combining our lightweight with Tensar’s system addressed both the poor soil and the steep slope needed to accommodate right-of-way limitations. Using our granular lightweight fill was the best option for the project,” he adds.

Details on Tensar’s Sierra® Slope Retention System

Tensar’s Sierra Slope System is an ideal and economical option when steeper slopes are needed due to right of way limitations or other constraints. The system can significantly reduce material and installation costs by eliminating many limitations imposed by soil conditions and minimizing fill requirements.

The geosynthetic material is layered in with the lightweight fill to provide slope stability. According to Tensar’s design engineer on the project, Vikas Cinnam, Tensar geogrids can be installed as an infill in almost any environment.

“That includes organic soils, saline soils, modified soils, alkaline soils, acidic soils, and soils with transition metals as long as the pH is greater than 3,” says Cinnam. “So, the use of lightweight is one example regarding the flexibility of Tensar systems,” he says.

Working With the Contractor

The contractor, D Construction of Coal City, IL, originally planned to use coarse lightweight aggregate on the project.

But Moore demonstrated that Arcosa’s fine gradation of lightweight aggregate would work equally well and fully meet all the project’s technical specification requirements.

“The slope on the side of the path was pretty steep,” says Chris Piazza of D Construction. “That made the job a challenge, and we had to layer the aggregate with the grid from the Sierra Slope system.”

“Arcosa did a fantastic job of helping us specify the right aggregate and got it there on time,” Piazza says.

Moore highlights that Arcosa Lightweight’s aggregate, with its lower density and higher internal friction angle, is ideally suited for challenging applications.

“In these situations, lightweight aggregate reduces the stress on poor subgrades,” Moore explains. “Its high internal friction angle and lower density also help decrease the lateral earth pressure on the system.”

- The Issue: The project faced two main challenges: constructing the bike trail on poor, compressible soil and managing a steep slope next to the trail, all while maintaining stability.

- What Arcosa Did: Arcosa Lightweight provided a fine gradation of lightweight aggregate (LWA) to reduce pressure on compressible soils and support slope stability using the Tensar Sierra® Slope Retention System.

- Why Lightweight Works: Arcosa Lightweight’s LWA was key in reducing stress on poor subgrades, minimizing lateral pressure, and providing a stable foundation despite challenging site conditions.

- Result: The project was successfully completed, with the lightweight aggregate contributing to both soil stabilization and slope management. The lightweight material met all specifications and improved the construction process.

- Key Quote: “Arcosa did a fantastic job of helping us specify the right aggregate and got it there on time.” — Chris Piazza, D Construction

- Industry Context: Lightweight aggregate was chosen due to its ability to address both soil compression and slope stability challenges. The project required precise layering of the aggregate with geogrids to ensure long-term stability.

- Lessons Learned: Using lightweight aggregate in challenging terrain offers significant benefits in reducing pressure on poor soils while providing slope stability.

- Call to Action: Learn more about how Arcosa Lightweight aggregates contribute to construction projects with complex soil and slope conditions.

- Project: 1.5-Mile Bike Trail Project

- Location: Orland Park, Illinois

- Customer: D Construction

- Client: Public Works / Local Municipality

- Project Size: 1.5 miles

Key Insights:

Quick Facts:

•

•

•

How Arcosa Helped:

•

•

Final Results

Key Quote

Context:

•

•

Explore Further

Additional Case Studies

Lightweight Aggregate Creates New Land for Cruise Ship Terminal

- Teaser: Port Canaveral, one of the world’s busiest maritime operations, now operates an advanced docking berth capable of handling today’s larger cruise ships. To achieve this, Arcosa provided the lightweight aggregate needed to extend the port into the water, creating stable ground for the expanded infrastructure.

- Article Body Text:

Jack Moore, Geotechnical Market Manager at Arcosa, explains, “Developers essentially created new land by extending the existing port into the water, using our lightweight aggregate to provide the necessary stability.”

Major Expansion

In 2012, Port Canaveral launched a $163-million campaign to improve and redevelop Cruise Terminal 3 (CT-3), which originally opened in 1983. A significant portion of this initiative included a $35-million rebuild of the existing wharf to accommodate today’s fleet of ultra-large cruise ships. The project began in 2018 with the demolition of an outdated, open-pile pier.

The new berth is a 1,309-foot-long facility designed for the Mardi Gras, the largest ship ever built for Carnival Cruise Line. The berth’s construction utilized expensive steel pipe and sheet piling. To ensure the project remained cost-effective, lightweight aggregate from Arcosa was used to fill behind the sheet piles.

“The low density and high internal friction angle of Arcosa’s lightweight aggregate played a crucial role in reducing lateral pressures on the sheet piles,” says Moore.

“This reduction allowed designers to decrease the gauge and length of the sheet piles, resulting in significant cost savings.”

Lightweight aggregate weighs about half as much as traditional fill materials like quarried stone. This advantage, combined with its high internal friction angle, reduced lateral forces by more than half, contributing to the stability of the structure.

“Lightweight aggregate’s low density and high friction angle make it an ideal choice for reducing lateral earth pressures and applied vertical stresses,” Moore adds.

Product Placement

On the jobsite, lightweight aggregate does not require special handling procedures. Crews easily placed the material using standard loaders, rollers, and plate compactors.

“Compaction is quicker and requires fewer passes compared to conventional fill,” explains Moore. “This allowed for faster fill placement and higher efficiency on-site.”

For this project, lightweight aggregate was delivered by both rail and truck. The material traveled roughly 600 miles from Livingston, Alabama, to the site.

“We used 550 railcars to deliver approximately 60,000 cubic yards of lightweight aggregate,” says Moore. “Everything was coordinated smoothly, ensuring that delivery and placement went off without a hitch.”

Successful Completion

The new berth at Port Canaveral Cruise Terminal #3 incorporates steel pipe and sheet piling bulkhead walls, a steel pipe pile tieback A-frame, and monopile and multi-pile shore and offshore mooring dolphins. It now accommodates next-generation Oasis-class cruise ships, which span over 1,300 feet and hold more than 6,000 passengers and 2,000 crew members.

- The Issue: The project required creating stable land where none existed by extending the port into the water, while reducing lateral forces on nearby structures to accommodate the large cruise ships of today.

- What Arcosa Did: Arcosa Lightweight provided lightweight aggregate to fill behind the sheet piles, allowing developers to extend the port into the water while reducing lateral pressures.

- Why Lightweight Works: Lightweight aggregate’s low density and high internal friction angle helped minimize lateral forces on the sheet piles, reducing material costs and enhancing stability.

- Result: The new berth now accommodates the Mardi Gras, Carnival Cruise Line’s largest ship, and supports next-generation Oasis-class ships. The project was completed efficiently and on budget, thanks to Arcosa’s lightweight aggregate.

- Key Quote: “Developers essentially created new land by extending the existing port into the water, using our lightweight aggregate to provide the necessary stability.” — Jack Moore, Marketing and Technical Manager, Arcosa

- Industry Context: The use of lightweight aggregate reduced the need for heavier materials, cutting costs and allowing the design to accommodate larger vessels without compromising structural integrity.

- Lessons Learned: Lightweight aggregate offers a cost-efficient, stable solution for projects requiring the extension of land, particularly in maritime applications.

- Call to Action: Contact Arcosa to learn how lightweight aggregate can enhance stability and cost-efficiency in your next large-scale construction project.

- Project: Port Canaveral Berth Expansion Project

- Location: Port Canaveral, Florida

- Client: Port Canaveral Authority

- Project Size: 1,309-foot-long berth

Key Insights:

Quick Facts:

•

•

•

How Arcosa Helped:

•

•

Final Results

Key Quote

Context:

•

•

Explore Further

Additional Case Studies

Lightweight Aggregate Safeguards Concrete Drainage System for Major Interstate Project

- Teaser: Interstate 22 (I-22), a key connection between Birmingham, Alabama, and suburban Memphis, Tennessee, handles roughly 75,000 northbound cars a day. When engineers began designing the interchange, they faced a unique challenge: constructing new traffic lanes over an existing concrete drainage system. The sheer volume of fill material required to bring the area to grade threatened to over-stress and potentially crack the vital stormwater culvert below.

- Article Body Text:

“The box culvert was quite deep, necessitating a significant amount of fill material to restore it to grade,” says Bill Wolfe, Marketing & Technical Manager for Arcosa Lightweight. “If ordinary soil or normal-weight fill material had been used, the loads could have been heavy enough to cause stress or even cracking in the culvert.”

Arcosa Lightweight’s structural lightweight aggregate provided the solution. Contractors filled three excavated areas with over 15,000 cubic yards of the product.

“To reduce the weight as much as possible, they placed the lightweight aggregate dry,” explains Wolfe. “Since the trench’s sides confined the material, they achieved the necessary compaction without having to add water.”

Manufactured in Livingston, Alabama

The lightweight aggregate used in this project was manufactured at Arcosa’s Livingston, Alabama plant and transported via multiple trucks to the job site, located approximately two hours north of the plant.

“The raw material, clay, is mined and stored in a controlled environment to manage moisture. It is then processed by heating it to approximately 2000°F in a rotary kiln. Once cooled, the material is transformed from clay into a ceramic, hard, and inert aggregate,” Wolfe explains. “The material is then crushed, screened, and graded according to the customer’s specifications.”

Results

After two weeks of placement, the culvert was once again buried deep underground, supporting new traffic lanes above. Motorists today pass through the area on I-22, formerly U.S. Route 78, without ever realizing the engineering challenge that had been solved beneath their wheels.

“This project exemplifies how lightweight aggregate can offer solutions to unique engineering challenges. The distinct properties of our product allow engineers to address issues that standard fill materials simply can’t resolve,” Wolfe concludes.

- The Issue: The engineering team needed to construct new traffic lanes on I-22 over an existing concrete drainage system. The substantial volume of traditional fill material posed the risk of over-stressing and cracking the culvert beneath.

- What Arcosa Did: Arcosa Lightweight provided 15,000 cubic yards of structural lightweight aggregate, reducing the weight of the fill and mitigating pressure on the culvert.

- Why Lightweight Works: The lightweight aggregate offered a high angle of internal friction and low density, reducing load on the culvert by more than half compared to traditional materials.

- Result: The project was successfully completed, and today, the newly constructed lanes on I-22 safely carry approximately 75,000 vehicles daily, protecting the culvert from damage.

- Key Quote: “This project exemplifies how lightweight aggregate can offer solutions to unique engineering challenges.” — Bill Wolfe, Marketing & Technical Manager, Arcosa Lightweight

- Industry Context: The innovative use of lightweight aggregate in this project marked a relatively new application for this material in protecting deep-buried infrastructure.

- Lessons Learned: Lightweight aggregate can dramatically reduce structural loads in sensitive infrastructure areas, making it a cost-effective and reliable solution.

- Call to Action: Learn more about how Arcosa Lightweight can provide engineering solutions for your project.

- Project: I-22

- Location: Birmingham, Alabama

- Customer: Archer-Western

- Client: Interstate Highway System (I-22 project)

- Project Size: 15,000 cubic yards of lightweight aggregate

Key Insights:

Quick Facts:

•

•

•

How Arcosa Helped:

•

•

Final Results

Key Quote

Context:

•

•

Explore Further

Additional Case Studies

Modernizing Infrastructure at the Carrollton Water Plant

- Teaser: The Carrollton Water Plant, a critical infrastructure asset for the east bank of Louisiana’s Orleans Parish, supplies around 135 million gallons of treated water daily to homes across New Orleans. Arcosa Lightweight stabilized the land for a new dedicated electrical substation, which now powers the modernized water and sewer systems. This project ensures long-term reliability and performance for one of the region’s most essential utilities.

- Article Body Text:

Cycle Construction Company, LLC, a family-owned general construction firm in Kenner, LA, handled the geotechnical phase. Project Manager Ethan Oddo explains, “Our task was to provide a blank slate. The site previously housed two large holding tanks, which had been abandoned. We removed all structures, walls, and slabs, then filled the area to grade with compacted materials. We used sand at the bottom, followed by two to three feet of Arcosa’s lightweight aggregate, and capped it with a foot of #610 limestone.”

Lightweight Plays Its Part

Cycle Construction used up to 20,000 cubic yards of Arcosa’s 3/16” fine granular lightweight aggregate to elevate the site. The lightweight aggregate reduced the density of the compacted fill, minimizing the impact of weight and lateral forces on nearby water basins.

“On three sides of the basin, we had active drinking water basins and tanks,” says Oddo. “Lateral forces couldn’t be too high, or we’d risk cracking the walls. Lightweight aggregate fit the bill perfectly.”

Cycle’s Civil Superintendent Dennis Grantham also praised the aggregate’s performance. “I had only seen lightweight aggregate used for landscaping, but its geotechnical performance exceeded my expectations. I thought compaction would be challenging, but we achieved great results,” says Grantham. “I expect to see more contractors using lightweight aggregate because of how well it works.”

Cycle’s Civil Superintendent Dennis Grantham also praised the aggregate’s performance. “I had only seen lightweight aggregate used for landscaping, but its geotechnical performance exceeded my expectations. I thought compaction would be challenging, but we achieved great results,” says Grantham. “I expect to see more contractors using lightweight aggregate because of how well it works.”

Grantham also commended Three C’s Trucking: “They do an excellent job. When the material is close at hand, we can place 2,000 to 3,000 yards a day. They’re fantastic at making things happen.”

Arcosa Lightweight also helped solve water intrusion issues on the site. “We had a lot of water on-site,” says Oddo. “But where we used lightweight aggregate, especially combined with geotextiles, we haven’t seen any issues with water intrusion.”

Increased Reliability

The new substation is a key part of New Orleans’ Sewerage & Water Board modernization, transitioning away from outdated steam-powered turbines to modern energy sources. This upgrade enhances the system’s reliability, especially during severe weather events.

“It’s critical to keep the water plant operational,” says Oddo. “We get hit by hurricanes and floods, and we lose power several times a year. When that happens, the Sewage and Water Board loses power, leading to low water pressure and boil water notices. This project was essential to solving that problem.”

According to a report from Entergy New Orleans, the project aims to increase reliability by routing power directly from the transmission system, which is less prone to outages. The new substation also provides the increased capacity needed to serve drainage pumps previously powered by aging infrastructure.

Lunch and Learns: Sparking Innovation

The Carrollton substation project originated from one of Arcosa’s Lunch and Learn sessions. Sales Representative Terry Lejeune explains,

“We host these sessions for offices unfamiliar with our products. We introduce Arcosa Lightweight, explain its benefits, and share ideas on how it can be used. That’s how the Carrollton project came about.”

For information on upcoming programs or to schedule a session for your team, call 1-800-342-LITE.

- The Issue: The project required stabilizing land for a new electrical substation in a location with poor soil conditions and significant water intrusion, all while minimizing lateral forces on nearby active water basins.

- What Arcosa Did: Arcosa Lightweight provided 20,000 cubic yards of lightweight aggregate to stabilize the substation site, addressing issues with compressible soil and lateral pressure on adjacent structures.

- Why Lightweight Works: The lightweight aggregate reduced the weight and lateral forces exerted on the surrounding water tanks and basins while maintaining stability, even in wet conditions.

- Result: The new electrical substation was successfully constructed, stabilizing the site and modernizing the power supply for the water and sewer systems, reducing the risk of outages.

- Key Quote: Lightweight aggregate fit the bill perfectly. It reduced lateral forces and helped stabilize the site without compromising the surrounding structures.” — Ethan Oddo, Project Manager, Cycle Construction

- Industry Context: The project was part of New Orleans’ broader effort to transition away from aging steam-powered turbines, improving the reliability of essential services.

- Lessons Learned: Lightweight aggregate offers an effective solution for challenging geotechnical applications, particularly in areas prone to water intrusion and compressible soils.

- Call to Action: Contact Arcosa to learn more about how lightweight aggregate can improve geotechnical stability in your projects.

- Project: Carrollton Water Plant Electrical Substation Project

- Location: New Orleans, Louisiana

- Customer: Cycle Construction Company, LLC

- Client: Sewerage & Water Board of New Orleans

- Project Size: Approximately 8 acres

Key Insights:

Quick Facts:

•

•

•

How Arcosa Helped:

•

•

Final Results

Key Quote

Context:

•

•