Internally Cured Concrete Enhances Water Tank Durability in Denver Water Projects

Internally Cured Concrete Enhances Water Tank Durability in Denver Water Projects

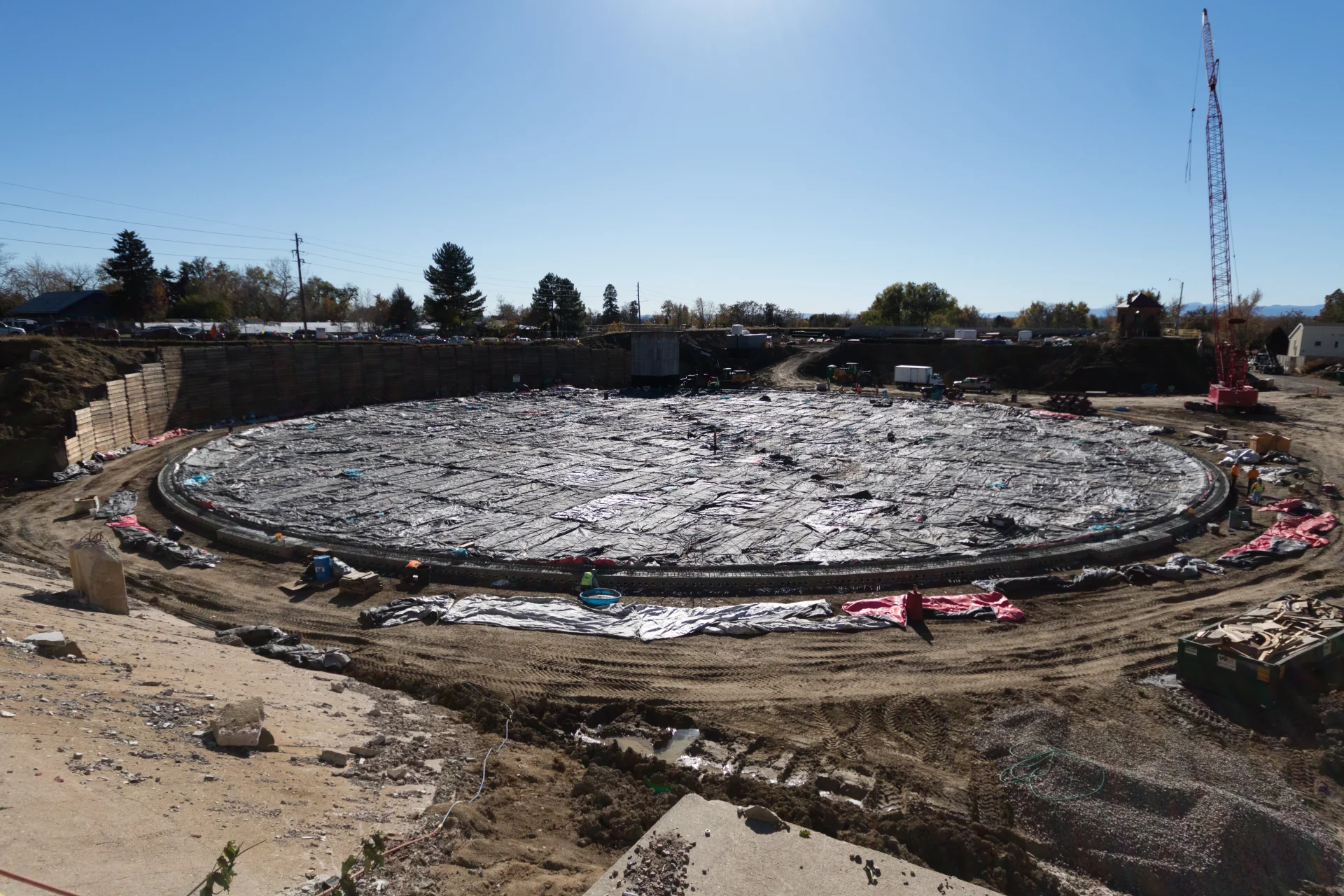

Denver Water is committed to ensuring safe and reliable water for its customers. To achieve this, the utility continually upgrades its system by replacing aging, large-capacity water storage tanks with more durable designs that are less susceptible to leaks. One way they have done that is through the use of Internally Cured Concrete (ICC).

This material has been successfully employed in multiple major tank replacement projects, including the Lone Tree, Highlands, and Ashland facilities, where it has helped to significantly reduce cracking and improve long-term performance.

At Lone Tree, a new 10-million-gallon underground water tank was constructed, providing a reliable water supply for the Southgate Water District and meeting fire response needs. In Highlands, Denver Water built a 7-million-gallon circular post-tensioned concrete water storage tank. At Ashland, two 20-million-gallon tanks were replaced as part of a major upgrade.

Why Internally Cured Concrete Works

Internally Cured Concrete has been crucial to the success of these projects by reducing shrinkage cracking and enhancing durability.

ICC uses expanded shale, clay, or slate (ESCS) lightweight aggregates, which absorb and gradually release water to sustain hydration throughout the concrete. This ensures a more uniform cure, preventing early-age shrinkage and cracking.

Bill Wolfe, Marketing & Technical Manager for Arcosa Lightweight, explains: “Internally cured concrete acts just like ordinary concrete, but with the additional benefit of reduced cracking and leakage. Once we demonstrated its effectiveness, Denver Water saw the results firsthand, and made it standard practice to use ICC in many of their tank replacement projects.”

Addressing Slab Placement Challenges

Placing large concrete slabs without joints is a challenge, especially in Colorado’s dry and windy climate. Erik Holck, P.E., Semi-Retired Civil Engineering Consultant, who spent 24 years at Denver Water, notes, “We constantly looked to improve the durability of our facilities, and Internally Cured Concrete was a great way to improve the quality, performance, and long-term durability of our large-scale treated water tanks.”

For the Lone Tree Tank No. 2 project, Holck and Robert Bates of Bates Engineering chose an ICC mixture to ensure both the base and roof slabs could withstand the harsh climate without succumbing to shrinkage cracking.

Lightweight Aggregate Utilized

To meet the specific project requirements, Aggregate Industries, now part of Holcim US, produced the high-performance ICC using prewetted expanded shale lightweight aggregates sourced from Arcosa’s Boulder, Colorado, operation. The aggregates helped achieve the desired strength, placing, and finishing characteristics for the slabs, walls, and columns.

According to Wolfe,

Broader Infrastructure Upgrades

Denver Water manages 31 treated water storage tanks across its service area. Since adopting ICC, eight of these tanks have undergone major upgrades, significantly reducing shrinkage cracking and enhancing durability. These upgrades are part of Denver Water’s broader initiative to improve infrastructure and deliver safe, reliable water to over 1.5 million people in the Denver metro area.

Internally Cured Concrete has proven to be a highly effective solution for reducing shrinkage cracking, improving durability, and streamlining construction schedules. As Holck explains,

With successes in projects like Lone Tree, Highlands, and Ashland, Denver Water plans to continue utilizing ICC across future tank projects to ensure long-term performance and reliability for its critical water infrastructure.

Additional Case Studies

TVA Utilizes Internal Curing for Historic Hydroelectric Dam’s Bridge Deck

The Wilson Dam bridge deck, part of the iconic 100-year-old hydroelectric dam on the Tennessee River in Muscle Shoals, Alabama, is ready handle another century of traffic. Arcosa Lightweight’s material played a pivotal role in these extensive repair…

Read More

A Look Back at the Union Pacific Dallas Intermodal Terminal (DIT)

The Union Pacific Dallas Intermodal Terminal (DIT) project stands as a testament to the transformative benefits of lightweight aggregate in improving the durability, strength, and overall performance of concrete paving. Notably, it remains one of th…

Read More

Internal Curing Gains Ground in Highway Construction: A Durable Solution

Internal curing is being recognized as a significant advancement in concrete technology. Today, the integration of lightweight aggregate (LWA) into concrete offers enhanced performance by reducing cracking, improving durability, and extending the se…

Read More