Asphalt Surfaces

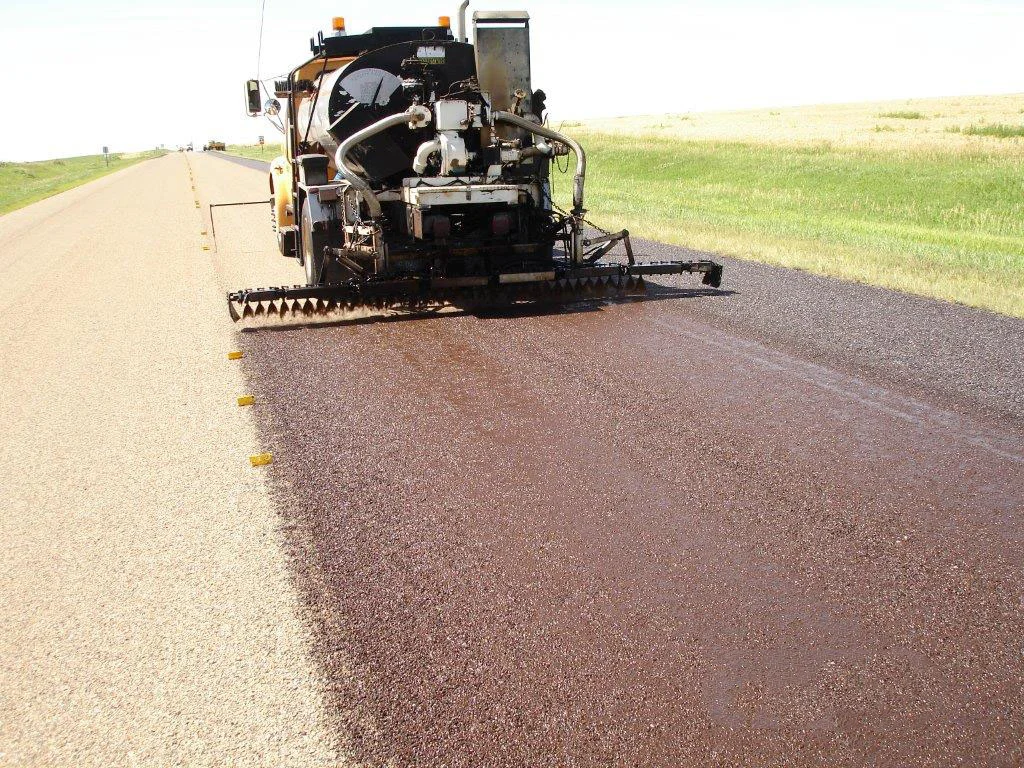

Arcosa Lightweight’s expanded shale and clay aggregates offer a high-performance solution for asphalt applications, providing superior skid resistance, reduced rutting, and improved durability for road surfaces.

By incorporating lightweight aggregates, asphalt surfaces gain resilience against wear and tear, increased longevity, and improved safety for drivers in both urban and rural settings.