As construction professionals and regulators push for sustainable solutions, the Expanded Shale, Clay,

and Slate Institute (ESCSI) is championing ESCS aggregates as a critical material in meeting the

industry’s

growing environmental demands.

With applications expanding in concrete durability, stormwater management, and geotechnical

stability, ESCSI’s Dr. Fariborz Tehrani emphasizes that lightweight aggregates are more than

just an

alternative—they’re a driving force for sustainable infrastructure.

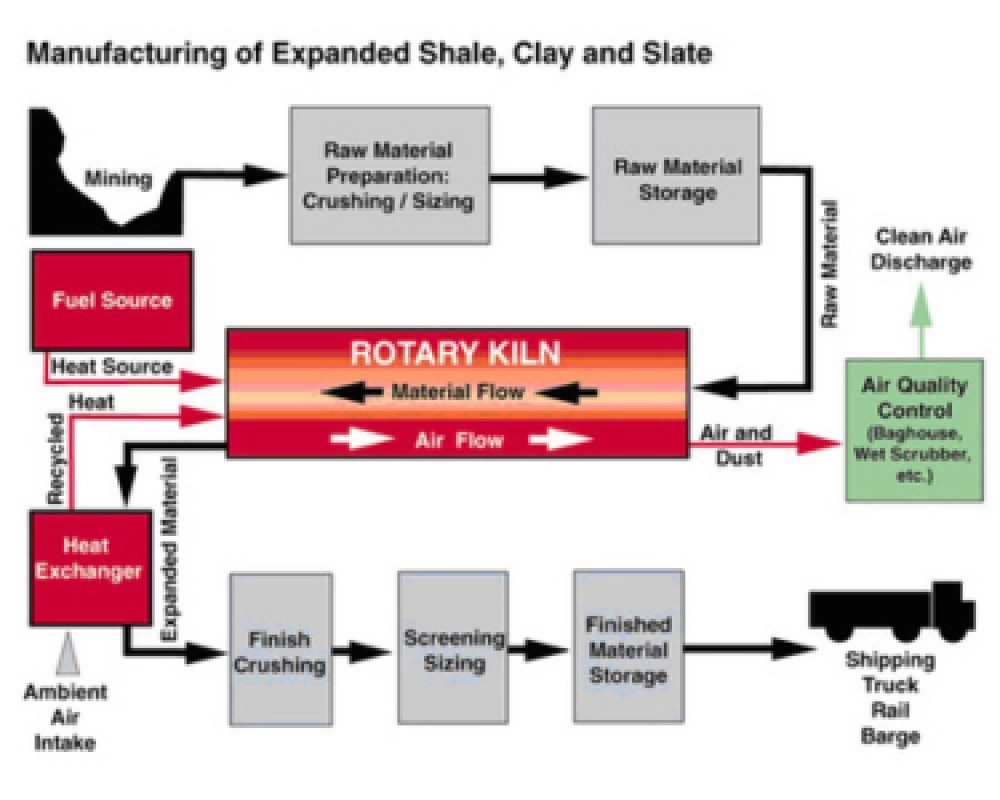

Expanded shale, clay, and slate (ESCS) aggregates are lightweight materials that provide

substantial

sustainability benefits across a range of construction and environmental applications. Created

by

heating raw materials in a rotary kiln, the unique production process causes ESCS to expand and

develop a porous structure, resulting in lightweight, durable, and highly versatile aggregates.

Enhancing Concrete Durability through Internal Curing

One of the primary sustainability advantages of ESCS is its application in concrete, where it improves

both performance and longevity. According to Dr. Fariborz Tehrani, Director of ESCSI,

“When incorporated into concrete mixtures, ESCS can enhance the material’s performance and

longevity. The porous nature of these aggregates allows them to absorb and release water, which is

particularly beneficial for internal curing.”

This process helps maintain moisture within concrete, reducing early-age

cracking and increasing structural durability.

Supporting Low-Impact Development with Stormwater Management

ESCS also contributes to sustainable urban planning through its role in

stormwater management. “These aggregates can be used in low-impact development (LID) techniques, such as

permeable surfaces and green roofs,” says Dr. Tehrani. “Their high porosity allows for efficient water

infiltration and retention, helping to mitigate urban runoff and reduce the burden on stormwater

systems.” This ability to manage urban runoff not only helps prevent flooding but also improves water

quality by filtering pollutants and supporting groundwater recharge.

Geotechnical Stability for Resilient Infrastructure

In geotechnical applications, the lightweight nature and high internal friction

of ESCS make it an excellent choice for soil stabilization and embankment construction.

“By using ESCS in these applications, engineers can reduce the overall weight of structures,

which is particularly beneficial in areas with poor soil conditions or seismic activity,” Dr. Tehrani

explains.

This reduction in weight contributes to safer and more resilient

infrastructure, enhancing the sustainability of construction projects.

Eco-Friendly Production and Local Sourcing

The production process of ESCS is efficient and environmentally friendly. “The

raw materials used for ESCS are abundant and often sourced locally, reducing transportation-related

emissions and supporting local economies,” notes Dr. Tehrani. Additionally, the expansive nature of ESCS

production means significantly less raw material is needed—up to one-third to one-half less than

conventional aggregates—to achieve the same volume in final products.

Driving Sustainable Construction Forward

With diverse applications and an eco-friendly production process, ESCS

aggregates are well-suited to sustainable construction. “Expanded shale, clay, and slate offer numerous

sustainability benefits, from enhancing concrete durability and stormwater management to improving

geotechnical stability and reducing environmental impact,” Dr. Tehrani concludes.